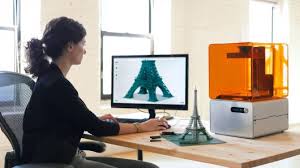

One of the great things about being involved in software development is belonging to a community that appreciates technological innovation. We attend cool events like Big Omaha, speak about software as a competitive advantage to local businesses, mentor young innovators in programs like Straight Shot and discuss the pros and cons of new and upcoming software product like Google Glass. So I finally decided to explore 3D printing, the much discussed and often maligned technology. I had only really heard about 3D printing in the political hotbed conversation of illicit gun manufacturing so I decided to take a closer look.

3D Printing for Dummies

3D Printing, also known as additive manufacturing, is the process of making a three dimensional object from a digital model using an additive process where materials are laid down in shapes specified by the model. It’s a decades old concept that has very recently started to take off. This blog published recently in The Economist is an interesting look at where the industry is headed and who has already incorporated it into their business model, including heavyweights Airbus, Boeing, GE, Ford and Siemens. One of the benefits of 3D printing is the obvious reduction in manufacturing costs. Companies are also taking advantage of the fact that you can now create harder to find replacement parts for a fraction of the time and cost of locating and shipping them. Another benefit on a larger scale would be the reduction in globalization as a result of more in-house design and manufacturing. Though these printers are still young and expensive, competition and innovation will likely drive costs down in the near future. Nike and New Balance are even pro-typing 3D shoe production. Imagine having the ability to design and make your own clothes. OK, maybe don’t do that.

Drawbacks

The prognosis for 3D printers is not all positive. Currently printing is a very slow process and it can take hours to print a single piece from a digital model. The costs for materials is also very high. Much has been written about the issue of 3D firearms production. The U.S. Department of Homeland Security and the Joint Regional Intelligence Center released a memo stating that “significant advances in three-dimensional (3D) printing capabilities, availability of free digital 3D printer files for firearms components, and difficulty regulating file sharing may present public safety risks from unqualified gun seekers who obtain or manufacture 3D printed guns.” Perhaps a bigger issue from a market standpoint would be peoples’ ability to actually replicate and produce their own 3D printers. Printers have a ways to go as well. Plastic molding and die have yet to disrupt durable goods manufacturers who deal in steel and heavier metals, relegating printers to the plastic goods markets.

Either way, as the quality of3D printers improves and the printed materials created from them, the quality and finish of prototypes is becoming harder to distinguish from things made in traditional factories. The technology is not going away and could change the way manufacturing and commerce are done dramatically. We’ll keep an eye on how three dimensional printing innovation unfolds. There are already a good number of 3D computer graphics software programs on the market. As a software and business consultant, Volano will see early on whether or not local Omaha businesses start to interface with this this technology.